Rejected product and production inefficiencies, fractured product and disappointed customers — the list goes on when facing breakage in crackers, fabricated potato chips and tortilla chips. Now, with the introduction of a new series of starch based texturisers, manufactures can reduce breakage and improve product quality through improved binding and dough cohesiveness — so sheeted and baked snack products can be delivered to consumers looking nearly as good as the day they were made.

Sheeted snacks are defined as food products that are made from dough that has been thinly sheeted (typically 0.75-1.5 mm) and then baked or fried to very low moisture content levels (typically around 2%). Because of the thinness and very low moisture content, these snacks have a light, crispy texture that consumers reach for again and again. However, the more brittle and delicate texture can lead to product breakage during the journey through the supply chain. In particular, breakage can be sustained during processing (by equipment and through oiling and/or seasoning process), during the packaging process and distribution. In distribution, breakage most frequently occurs due to the handling of the material by plant personnel, the shipper, the store selling the product and shoppers. The shoppers who bring the product home experience the fallout when they see or try to eat the broken or pulverised pieces at the bottom of the bag.

Breakage is an issue that can impact both retail sales and manufacturer costs. Excess breakage results in products that have to be rejected. And rejected product can add up to a significant cost — and loss — due to wasted raw materials. Depending on the formulation, manufacturers may be able to utilize the broken material via rework, but this typically is only feasible up to a very low level. Having unsellable product with high amounts of breakage can also result in increased manufacturing and labour costs when the product has to be remade.

Consumers have certain product expectations, such as flavour, texture, the usability of the product and value for their money. Causing disappointment with small broken pieces or fines that are difficult to consume and provide little texture appeal can end up reducing the perceived value of the product — especially if it ends up in the garbage or as a mess on the floor — which can make it less likely that the consumer will repeat their purchase, limiting your sales potential. Also, breakage can act as an impediment to the creation of the perfect bite of crunchy enjoyment for consumers, as manufacturers may abandon new concepts when not able to effectively control breakage.

Snack manufacturers typically attempt to minimise and control product breakage through the use of packaging solutions. A pillow pack for example, where gas (typically nitrogen) is forced into a snack bag during packaging is used to both modify the atmosphere of the packaged foods headspace to reduce spoilage and rancidity of the product, and to create a cushion in between bags to provide a degree of protection from breakage. Packaging solutions, while they help, cannot help strengthen the structure of the chip itself. Now manufacturers of baked sheeted snacks can reduce breakage even further with ingredient solutions.

An ingredient approach using either clean label native or modified starch-based texturisers can be used to provide reduced breakage in sheeted snacks and are “built-in” up front during formulation. These starch-based products are used to improve the resiliency and the strength of the sheeted snack. The texturisers can be easily incorporated into the dough make-up stage as a drop-in solution and will not significantly impact the sheeting or baking process.

Examining the reduction of breakage in sheeted snacks

A systematic, data driven approach, known as DIAL-IN®Technology, was taken to examine the effect of starch selection on breakage in sheeted snacks. The amount of chips broken following a defined agitation period was compared in sheeted products made with standard waxy corn-based materials versus chips made with three different specialty texturizers.

Figure 1: Fabricated baked potato chip formulation used to evaluate the effect of starch selection on breakage in a sheeted snack.

Specialty pre-gelatinised starch is used at a high level in the baked potato chip formulation (23% weight/unit weight on a dough basis) in order to help develop cohesive and sheetable doughs. The pre-gelatinised starch also provides expansion during baking and is a texturising agent in the final product. This functionality is summarised in Figure 2. The most common type of pre-gelatinised starch used for this application is based from waxy corn. These starches are very effective at providing a cohesive dough rheology that provides binding, ease of sheeting and good expansion. However, they can create excess expansion and make the product easier to break.

Figure 2: Functionality of pre-gelatinised starch in a sheeted snack application

Figure 3: Pre-gelatinised starches used in breakage study

Fortunately, there are specialty starches that can provide the same dough and sheeting properties as the pregelatinised starches, but deliver a more resilient sheeted snack more likely to survive agitation and abuse. These specialty starches, listed in Figure 3, were evaluated in the breakage study.

Fabricated baked potato chip production trial procedure

To make the fabricated baked potato chip formulation in Figure 1, all of the samples were processed at a snack manufacturing facility with commercial mixing, sheeting and baking lines.

- Mixing process: Dry materials were added to a Collette Mixer (high speed). Water was gradually added to mixer bowl while mixing. Dough was mixed for 2 minutes, 30 seconds. After mixing, dough was examined to determine if enough water was added. If necessary, more water was added. Otherwise, dough was deposited directly on sheeter before final gauge roll.

- Sheeting process: Dough was deposited directly before final gauge roll and sheeted to a thickness of 0.8-0.9 mm. Dough was then cut to hexagon shape and conveyed into convection oven.

- Baking process: A two-zone convection oven was used for baking. The first zone was set to 510°F and the second zone was set to 365°F, with a total baking time of 1.5 minutes.

- Drying process: Product was sent through dryer to reduce final moisture content. Drying temperature was set to 255°F for 5 minutes in order to achieve a final moisture content of approximately 2%.

- Collection process: One hundred fully intact chips from each batch were taken from the production line and placed into a sealed plastic bag to go through breakage testing at the Ingredion Idea Labs® global innovation center in Bridgewater, NJ.

Breakage assessment procedure

The manufactured fabricated baked potato chips were assessed for breakage under the following controlled conditions, using the 100 fully intact chips from the production trial:

- Immediately off of drying oven, 100 complete and unbroken chips were collected and placed in a resealable bag. The bag was ensured to be sealed and carefully transported to the lab.

- The weight of 50 full, unbroken chips was recorded. Fifty full, unbroken chips were placed into a food tumbler (Reveo Marivac Food Tumbler, Model Number 38229).The tumbler was turned on and allowed to tumble for 30 minutes at a speed of 16 revolutions per minute.

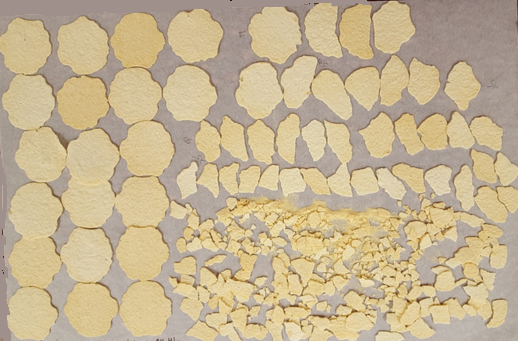

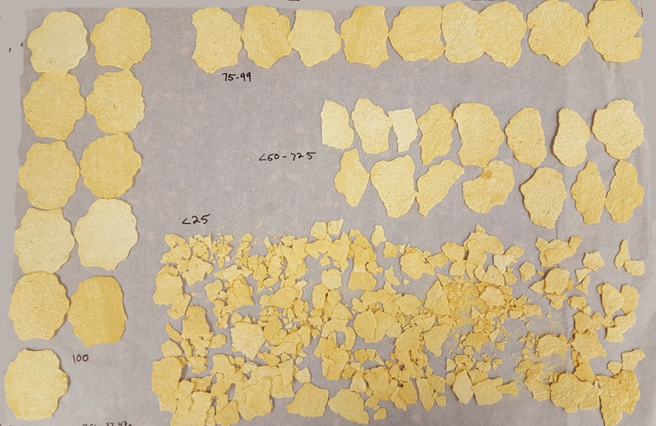

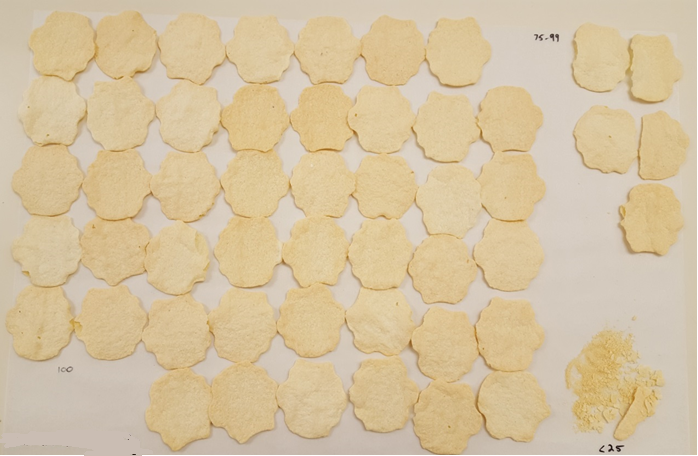

- Chips were spread across parchment paper and separated into categories: Fully intact chips, chips that are greater than 75% but less than 100% intact , pieces of chips that are 25-75% intact, and chips that are less than 25% intact, defined as “fines.”

- Pictures were taken of chips spread across parchment paper and separated into categories.

- Weight of chips in each category was taken and recorded.

Breakage study results

The results of the tumbling showing intact chips (in blue) versus broken chips/chip fines (in red) are shown in Figure 5. The standard modified pre-gelatinised waxy corn starch (and the standard native pre-gelatinised waxy corn starch) had extensive breakage as can be seen in Figures 6 and 7. Both pre-gelatinised prototypes had over 50% breakage following the 30 minute tumbling cycle. Pictures of the chips following tumbling are shown below.

When the pre-gelatinised starch was switched to the specialty corn and tapioca starches, the breakage was significantly reduced. After the tumbling process, between 80-90% of the chips were intact for each fabricated potato chip prototype. Pictures of these chips are also shown below (Figure 8-10) and the differences can be seen versus the standard pre-gel waxy corn ingredients.

Figure 5: Results of breakage study showing intact chips (in blue) versus broken chips and chip fines (in red)

The specialty texturisers tested in the study were able to significantly reduce breakage in fabricated baked potato chips compared to more standard pre-gelatinised waxy corn-based ingredients. It should be noted that this change in starch will create different expansion and hardness properties, with modified tapioca starches A and B contributing less expansion and higher level of hardness. Manufacturers will need to keep this in mind when making a starch selection.

Breakage is a costly issue for snack food manufacturers because of rejected finished product, decreased consumer satisfaction and consequently reduced repurchase interest. The rejected finished product results in increased raw material costs, while decreased consumer satisfaction and missed new product opportunities can hurt growth.

Standard waxy pre-gelatinised corn-based starch ingredients are often used in sheeted snacks to help with dough and sheeting properties as well as to provide expansion during baking and final texture. However, the ingredients typically create a very crispy and delicate texture that can easily break during seasoning, packaging and distribution. Manufacturers need the ability and flexibility to control breakage in their final product while also ensuring specific textures.

With Ingredion’s DIAL-IN® Technology approach and line of highly functional specialty texturisers, manufacturers now have the ability to reduce breakage in sheeted snacks. Depending on the specific ingredient used, manufactures can optimise dough and sheeting properties, customise texture and improve consumer acceptability of their products.

The speciality starches examined in this study are products that have been demonstrated to have significantly less breakage than a standard pregelatinised waxy corn starch. Ingredion is a global company a portfolio unique to each region we serve, so contact us to learn more about which specific products we can recommend for your business.