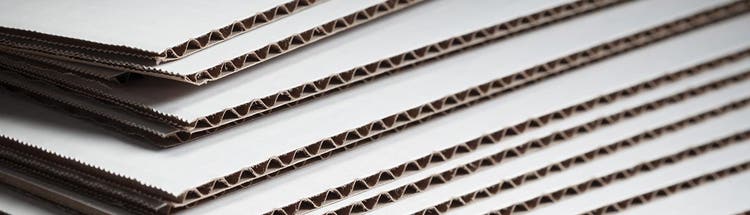

Board solutions

Start getting more green for your packaging

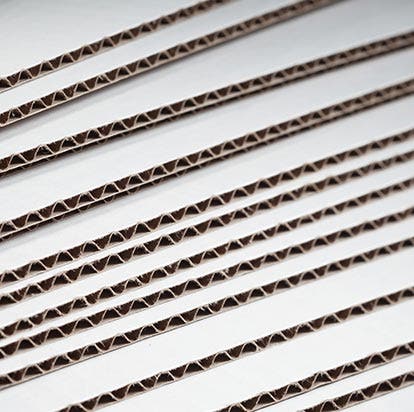

For stronger, lighter cartons and containerboard, seek out more innovation in your additives, coatings and adhesives. At Ingredion, that's what we deliver — and we'll show you the way to achieve improved productivity and cost-effectiveness for your unique strength, printability and barrier requirements. From robust wet-end solutions that reduce basis weight and improve drainage and retention to smarter binder and surface solutions delivering greater performance and value, we bring deep understanding of packaging and starch chemistry to meet your challenges.

Boost productivity with wet-end/dry-end solutions

Our linerboard production solutions help you replace synthetics, deliver the dry strength development, increase machine speed and improve retention you need to be most productive.

Enhance finished product performance and accomplish your dry-end goals

With OPTIBOND®/OPTIPRO® wet-end starches and TOPCAT®/REDIPRO® high-charged cationic ready-for-use natural polymers, plus surface starch technology when needed with PENFORD GUM® modified starches and PENFILM® surface binders, we can help you:

- Open wider operating windows due to lower addition rate

- Save energy with the reduced drying demand

- Gain freedom to improve current products and create new ones — without having to buy new equipment or greatly alter processes

Coatings deliver strength and printability

For optimal binding strength plus quality appearance and printability, look to operator-friendly, no-VOC PEN-COTE® L and PEN-COTE® D binder solutions. Outperforming other naturally derived binders, the solutions enable solids content up to 50% to help cut the need for viscoscity modifiers. Available both as ready-for-use liquids and completely soluble powders to easily integrate into your processes.

Bond with eco-friendly adhesives

Reduce your carbon footprint with environmentally friendly, natural and renewable PENLAM® adhesives which deliver high binding strength, superior runnability, easy cleanup and biodegradability with no VOCs. We'll help you customize your formulation to meet your manufacturing needs for percent of solids, viscosity and molecular weight.

Featured ingredients for containerboard (corrugated case material [CCM], paperboard, linerboard, corrugating medium, fluting)

CORN PRODUCTS®

pearl starches

The information described above is offered solely for your consideration, investigation and independent verification. It is up to you to decide whether and how to use this information. Ingredion Incorporated and the Ingredion group of companies make no warranty about the accuracy or completeness of the information contained above or the suitability of any of their products for your specific intended use. Furthermore, all express or implied warranties of noninfringement, merchantability or fitness for a particular purpose are hereby disclaimed. Ingredion Incorporated and the Ingredion group of companies assume no responsibility for any liability or damages arising out of or relating to the foregoing.