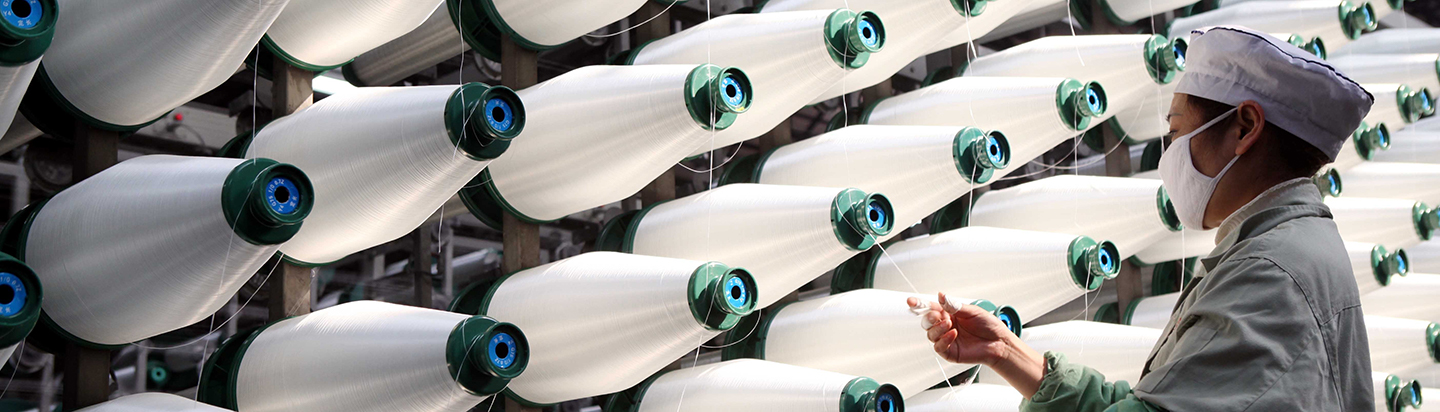

Exploit the growing demand for glass yarns with affordable, high performance sizing starches

Ingredion’s sizing starches will help you to successfully exploit the growing global demand for glass yarns. They will enable you to manufacture yarns with the performance and functionality your customers demand, whilst achieving improved productivity and affordability which can help to boost your profits. Selling directly to you through our own experienced starch specialists, Ingredion offers quality, consistency and security of supply. Ingredion sizing starches will also help eliminate synthetic alternatives and boost your green credentials.

The global glass fibre market is currently growing at around 7% per annum and is expected to be worth more than US$11 billion in 20171. This growth is being driven by an increasing demand in key sectors such as:

In these sectors, glass fibre is replacing traditional materials in a range of applications as manufacturers recognise the benefits it brings in terms of weight reduction, superior performance and lower cost. However, glass fibre manufacturers face a challenge from energy costs and the price movements of inputs. Sizing is essential to the manufacturing process and choosing the correct sizing is critical because it has an impact on how the fibres behave during processing and how they perform as part of a composite.

Sizing starches from Ingredion offer quality, flexibility and cost effectiveness, helping you to deliver the performance your customers demand at a lower cost than if you had used starch alternatives. They will allow you to optimise your glass fibre products for particular applications. Furthermore, our technical mastery of starch and unique portfolio of products will provide you with the scope to differentiate your products. In addition, when you work with our starch scientists, they can help you innovate to create completely new products.

Ingredion offers modified and unmodified starches based on both maize and potato technology:

Ingredion is an acknowledged global leader in advanced starch technology. We work with growers who produce maize especially for us and have developed our own proprietary high amylose starch technology.

With quality control and consistency good enough to meet the requirements of the world’s toughest food authority regimes, you can rely on our sizing starches to help you create products that deliver competitive advantage time after time. In particular, companies involved in the production of glass yarn for electronic and construction applications can achieve significant benefits.

1. Koncept Analytics, (2013). Global Fiber Glass Market Report - 2013 Edition. Research and Markets.

The information described above is offered solely for your consideration, investigation and independent verification. It is up to you to decide whether and how to use this information. Ingredion Incorporated and the Ingredion group of companies make no warranty about the accuracy or completeness of the information contained above or the suitability of any of their products for your specific intended use. Furthermore, all express or implied warranties of noninfringement, merchantability or fitness for a particular purpose are hereby disclaimed. Ingredion Incorporated and the Ingredion group of companies assume no responsibility for any liability or damages arising out of or relating to the foregoing.